Several types of Axle are available:

Cantilever/Stub Axle

The axle is fixed on one end only. This introduces a bending moment based on the gap distance and wheel type.

Single

For use with a single wheel only.

Double

A through axle with brackets supporting the axle. The wheels are mounted on the end of each axle.

Bracket/Fork

The axle is supported on both sides with the wheel centrally mounted.

Through Axle

The axle is supported by a pair of mountings, which can support the axle either side of the wheel position.

Live Axle

This is a solution for a driven application. Various systems can be utilised to drive and rotate the axle.

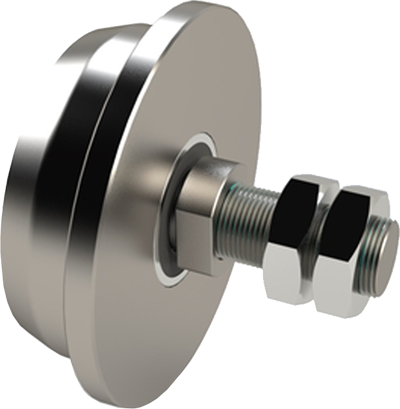

Single Flanged Wheel and Axle Assembly

Commonly used for applications including overhead rail, RSJs, Channel, and other guided applications. The assembly is an easy way of reducing fitting time. Specifications can vary to suit more demanding applications. Stainless steel, cast iron and some synthetic materials can be used.

- Guided application

- High load capability

- High humidity environments

- Full immersion applications

- Non sparking applications

- Chemical exposure applications - check suitability

- Low wear/long life requirement

- Low rolling resistance

- Operating temperature range is between -50 to +800 degrees Centigrade

- Suitable for various rail materials and profiles

Bores can be changed to bushes for environmentally difficult or demanding applications.

Tread profiles can be machined to suit Parallel flanged channel, Rolled steel channel,Tapered channel, Metric and Imperial sizes, standard and special rail profiles including round bar.

Standard steel temperature range -30 to +120 degrees Centigrade Derating will affect at the higher end of the temperature range, so consultation with your specialist contact is required.

For higher temperatures other materials may be required, for example cast iron.

Bearings will need to be changed to high temperature variants. Alternatively a bush may be required.

Lubrication is another matter for consideration with higher temperature applications.